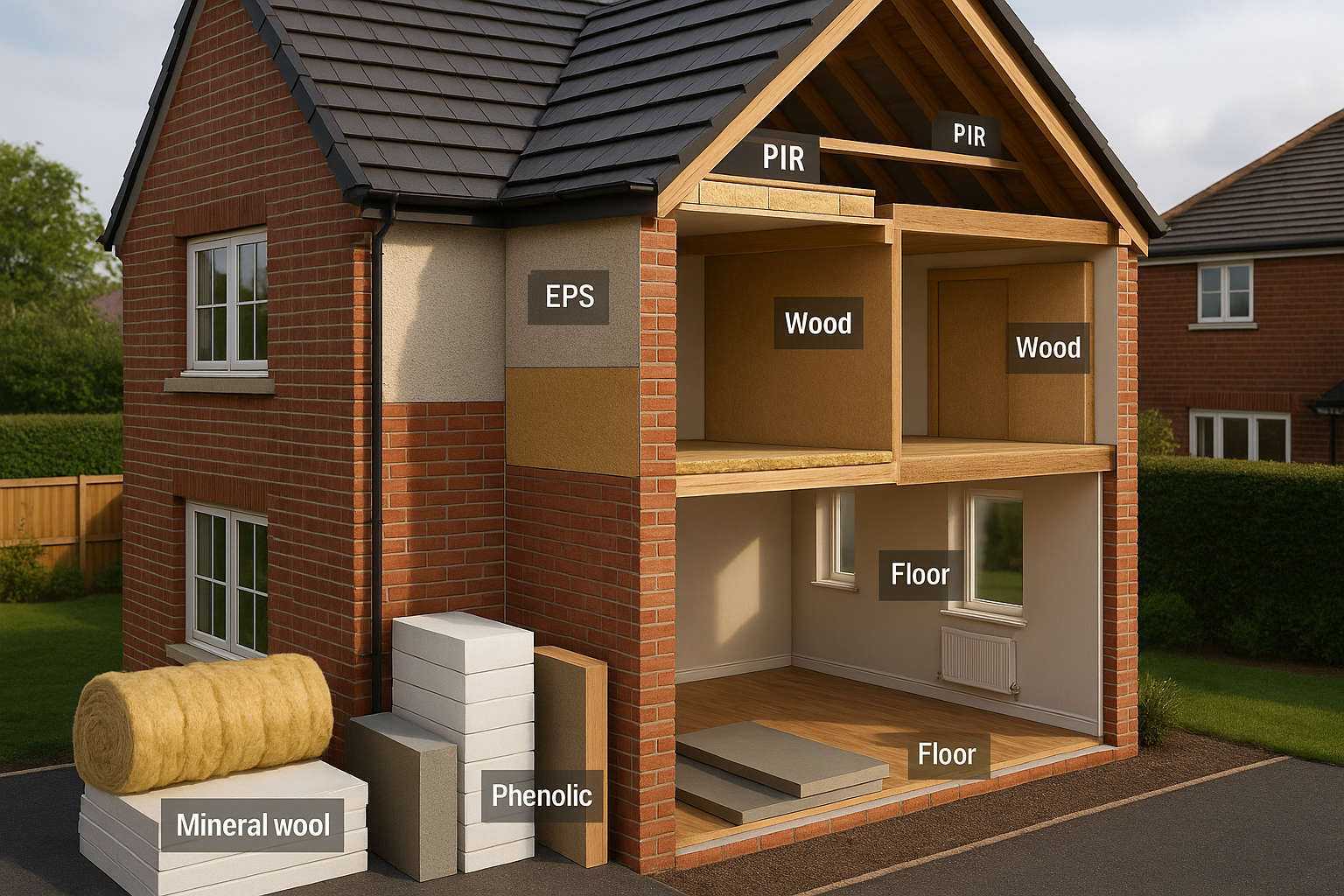

The Best Thermal Insulation for Buildings: A Plain-English UK Guide

Why the material really matters

With energy bills rising and weather extremes more common, choosing the right insulation makes a visible difference to comfort and running costs. The challenge? There are several good options - each with different strengths. This guide simplifies the decision so you can pick confidently.

How to choose (quick framework)

- Space available: tight cavities and shallow rafters favour higher performance per mm.

- Moisture risk: plan for ventilation, vapour control and water resistance where needed.

- Fire behaviour: check combustibility ratings and follow regulations.

- Acoustics: some materials absorb sound better than others.

- Budget & install: balance upfront cost, ease of fitting and long-term savings.

Material by material

Mineral Wool

Made from natural or recycled stone/glass fibres. A popular, versatile choice for lofts, stud walls and intermediate floors.

- Pros: good thermal and acoustic performance; non-combustible; easy to trim and fit.

- Considerations: protect from moisture ingress; performance drops if compressed.

- Best for: loft layers, between studs/joists, acoustic upgrades.

Expanded Polystyrene (EPS)

Lightweight rigid boards often used in external wall systems and floors.

- Pros: budget-friendly; easy to handle; consistent board sizes.

- Considerations: combustible; avoid solvent-based adhesives; needs careful detailing near heat sources.

- Best for: EWI systems, floors, packaging thermal breaks.

Phenolic Foam

High thermal performance in thinner build-ups — useful where depth is at a premium.

- Pros: strong performance per mm; helps reach target U-values with less thickness.

- Considerations: higher upfront cost; follow manufacturer guidance on fixings and linings.

- Best for: tight roof and wall build-ups.

Wood Fibre

Natural, breathable boards that contribute to moisture buffering and summer comfort.

- Pros: vapour-open; helpful acoustic properties; low embodied aesthetic.

- Considerations: thicker build-ups; protect from liquid water during install.

- Best for: eco-retrofits, internal wall linings in breathable build-ups.

Polyurethane (PIR)

Rigid boards with strong thermal resistance, similar family to PIR.

- Pros: high performance; relatively low thickness for given targets.

- Considerations: typically combustible; accurate cutting and tight joints are key.

- Best for: roofs, linings and floors where space is limited.

Aerogel

Ultra-slim, premium solution for the most space-constrained areas.

- Pros: excellent thermal performance at minimal thickness.

- Considerations: expensive; typically used as part of a hybrid detail.

- Best for: reveals, bridges and hard-to-insulate details.

Quick comparison (at a glance)

| Material | Thermal per mm | Acoustics | Moisture behaviour | Fire behaviour | Typical uses |

|---|---|---|---|---|---|

| Mineral Wool | Good | Strong | Keep dry; VCL where specified | Non-combustible | Lofts, studs, floors |

| EPS | Moderate | Limited | Low water uptake; avoid solvents | Combustible | EWI, floors |

| Phenolic | Very high | Moderate | Follow manufacturer guidance | Check system rating | Thin roofs/walls |

| Wood Fibre | Moderate | Good | Vapour-open; protect from wetting | Check board rating | Breathable linings |

| PIR | High | Limited | Seal joints; manage vapour | Combustible | Roofs, linings, floors |

| Aerogel | Excellent | Limited | As per system | As per system | Reveals, bridges |

Making the choice

Match the material to the location and objective: some excel in slim build-ups, others in acoustic control or breathability. Think long-term — good detailing and installation protect performance for years.

Need a hand?

Buy Insulation can help you compare options for your project and supply the right materials at competitive prices.

Tip: if depth is tight, consider a hybrid build-up (e.g., rigid board plus mineral wool) and confirm the U-value for compliance.